SPM

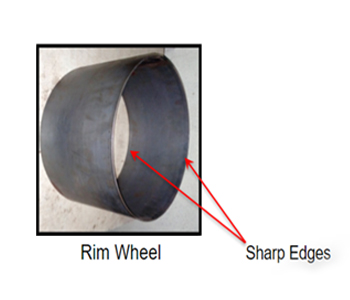

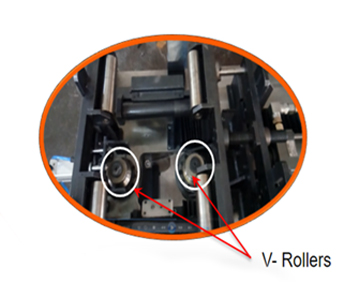

EDGE CONDITIONING SPM

Customer : Kalyani Maxion Wheels Ltd.

- SPM for removal of sharp Edges of the RIM Wheel & used for shaping the edges 1mm x 45 º by pressing between two V-shaped tools by rotation for 360º+ Overlap.

- It consists of PLC+VFD based control system along with Hydraulics. The cycle time of this SPM is 6-sec inline operation synchronized with Upstream & Down stream machines.

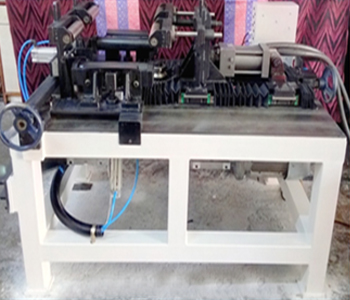

Welding JOB SPM

Customer : Chromewell Industries PVT. LTD.

Automatic welding SPM with ball screw, LM guide & servo-driven slide to move torch linearly on the job. Welding length speed & length can be set and changed by HMI & PLC. Job Holding Fixture is designed which has pneumatic actuators. This machine is used for welding the John Deer tractor part.

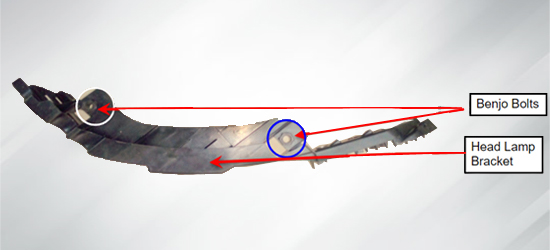

VW Headlamp Bracket Sleeve & Banjo Bolt Assembly

Customer : International Automotive Components (I) PVT. LTD.

- SPM built for fitting of Benjo Bolts & sleeve pressing on headlamp bracket of VW car.

- Benjo bolt fitting accuracy is +/- 0.25mm axially(height), self-tapping operation with a maintained pitch of threads.

- The accuracy is achieved by using motor & special lead screw, nut. LVDT feedback measures & controls the height. It is PLC based system with LVDT feedback & safety features.